© 2017-2018 Shangbaotai Machine Technology (Kunshan) Co., Ltd. All rights reserved. Site Map

Many snack-producing companies rely heavily on their noodles packaging machines, but if they break down, the level of production and capacity utilization will decline greatly.

Additionally, regular maintenance may maximize revenues and extend the service life of your packing machine.

A piece of equipment that is properly maintained will function optimally for a very long time.

To make your noodles packaging machine operate rapidly and even more efficiently as well as getting you started on the road to increased production level, we are providing some expert advice on appropriate maintenance checklists for your packaging equipment.

A proactive maintenance schedule must be created and implemented after the packing machine has been installed.

For instance, properly lubricating the device, inspecting, and changing damaged parts might stop potential or unforeseen breakdowns from happening.

The primary maintenance tasks are as follows:

Ø Changing the lubricant periodically.

Ø Carry out frequent testing and record the machine data in a timely manner.

Ø Always check for loose connections and tighten fasteners.

After you purchase a packing machine, your supplier must give you a list of suggested replacement parts.

This list should be divided into part classes according to wear so that you may properly arrange your parts stockpile.

High-wear parts

These components have a longer lead time, a limited-service life, or are non-standard goods.

Medium-wear parts:

These components have a long service life and could malfunction at any time.

Low-wear parts

These parts must never malfunction

Making inventories beforehand will allow you to change worn-out components as soon as possible without stopping or reducing production levels. Keeping a stockpile of high-wear parts is strongly encouraged.

Waiting for a part to be manufactured or delivered would be the last possible option you want to take whenever your equipment breaks down.

Huge profits are lost every minute your machine is not functioning during production periods.

When a particular machine element or part is considered moot and is no longer usable, packaging equipment and software undoubtedly need to be upgraded, and occasionally they even need to be replaced.

Noodles packaging Equipment is no exception to today's rapid technological advancement.

To find out how the machinery updates are developing, get in touch with the packaging machine's supplier on a frequent basis. Make an updated plan and invite professionals to the facility so they can inspect, diagnose and prescribe upgrades as necessary to help enhance productivity.

Be proactive, not reactive, with regards to the functionality of your noodles packing machine.

For increased yields throughout the lifespan of your packaging machinery, apply the maintenance checklists listed above right away:

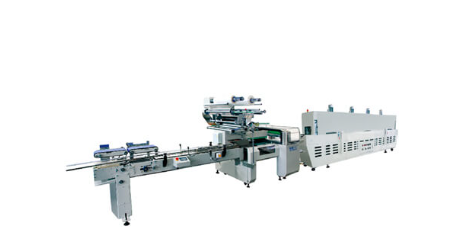

We are renowned all over the world as a premier supplier of superior noodles packaging machines for items that are challenging to fill.

Both the biggest companies in the packaged food industry and the smaller clients use our products on the majority of their ready-meal lines.

Get in touch with us right away to learn more about installing and maintaining a machine for packaging noodles.