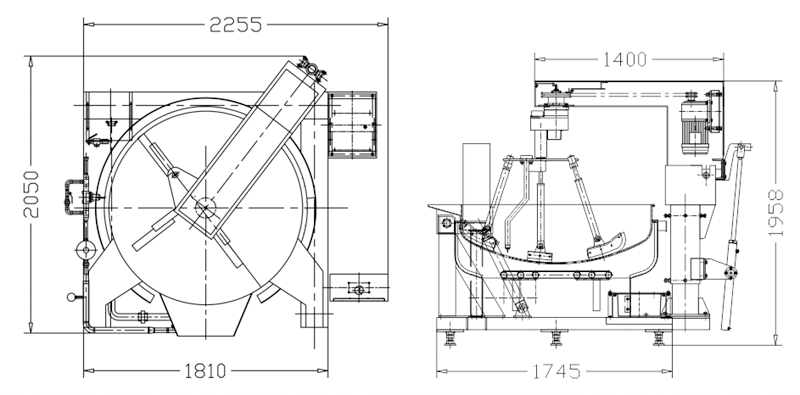

Customized Seasoning Sauce Cooking Machine

TCM-4100 frying and stewing machine is provided with the pot made by the stainless steel 316 imported from Japan, in which the weld joints are subject to flaw detection by X-ray scanning. The machine using a hydraulic control system and the PLC programming can be operated by a touch screen. The stirring system with raised tracks is used to scrape sauce uniformly and prevent the sauce from sticking to the pot. It has the memory function of running 16 products and can set the stirring technology on the touch screen. The temperature can be automatically determined. This machine is applicable for such processing technologies as steaming, stewing, frying, stir frying and refining various flavorings, vegetables, meats and oils, etc. Compressed air is used for combustion supporting to achieve full burning and thus save the cost. Currently, TCM-4100 frying and stewing machine is the largest domestic full-automatic frying and stewing equipment.

Apply to steaming, cooking, frying, stir-frying, refining and other processing methods of various seasoning food, vegetables, meat, fried food and etc.

The pot body is made of SUS316 material;

Use hydraulic control system;

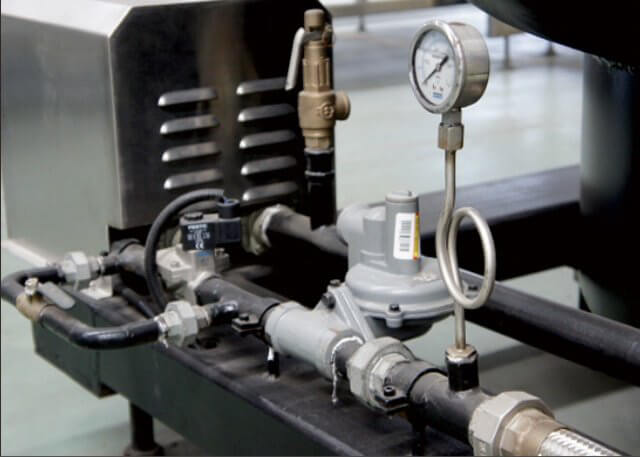

The gas is combustion-supported by compressed air;

The temperature is automatically measured.

|  |

| Machine Body | Stirring Track |

| Capacity | 500L | Voltage | 3phase 380V 50Hz |

| Stirring speed | 20-30 RPM | Gas consumption | 155,000 Kcal/h |

| Total power | 4.0KW | Automatic grade | Automatic |

|  |

|

Planetary scraper fit firmly with the pot to keep the whole pot being scrapped. The heat detector directly touched the sauce, so as to automatically adjust scrapping speed according to the temperature. | Compressive oxidant gas is applied and the pressure can be adjusted to make the combustion more sufficient and reasonable. | The adjustment of the consumption of combustible gas makes combustion sufficient; the temperature is easily to be regulated. |