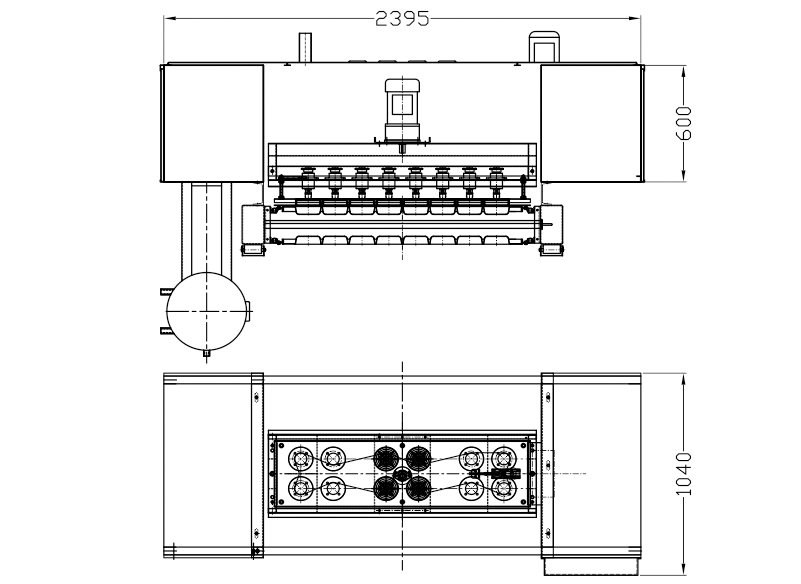

Customized Full Automatic Noodles Finisher

Unattended noodle frying operation is achieved by the automatic noodle finisher to effectively reduce labor costs. The high-speed production line is provided with a three-low rotary finishing tuyere, controlled by a PLC and synchronously operates with the fryer to provide better noodle finishing effect. An external arrangement mode is used for all electrical control elements to effectively reduce damage probability resulting from high temperature and facilitate subsequent care and maintenance.

The operation is synchronized with the oil bath;

Noodles finishing is complete and the appearance is beautiful;

Labor-saving.

Unmanned noodles frying system can efficiently lower labor cost. High-speed production line adopted three rows of rotation finishing blower, with PLC programmer control, operating synchronized with the frying machine to bring better finishing effect.

|  |

| Before Finishing | After Finishing |

| Working speed | 36row/min | Voltage | 3phase 380V 50Hz |

| Total power | 2.25KW | Automatic grade | Automatic |

|  |  |

Continuous rotation blowing makes noodles complete, smooth and beautiful in the appearance. | Equipped with solo gas storing tank, the pressure is stable and the shape is structured. | Cam-style synchronous follow makes finishing more stable; finishing time is also sufficient. |